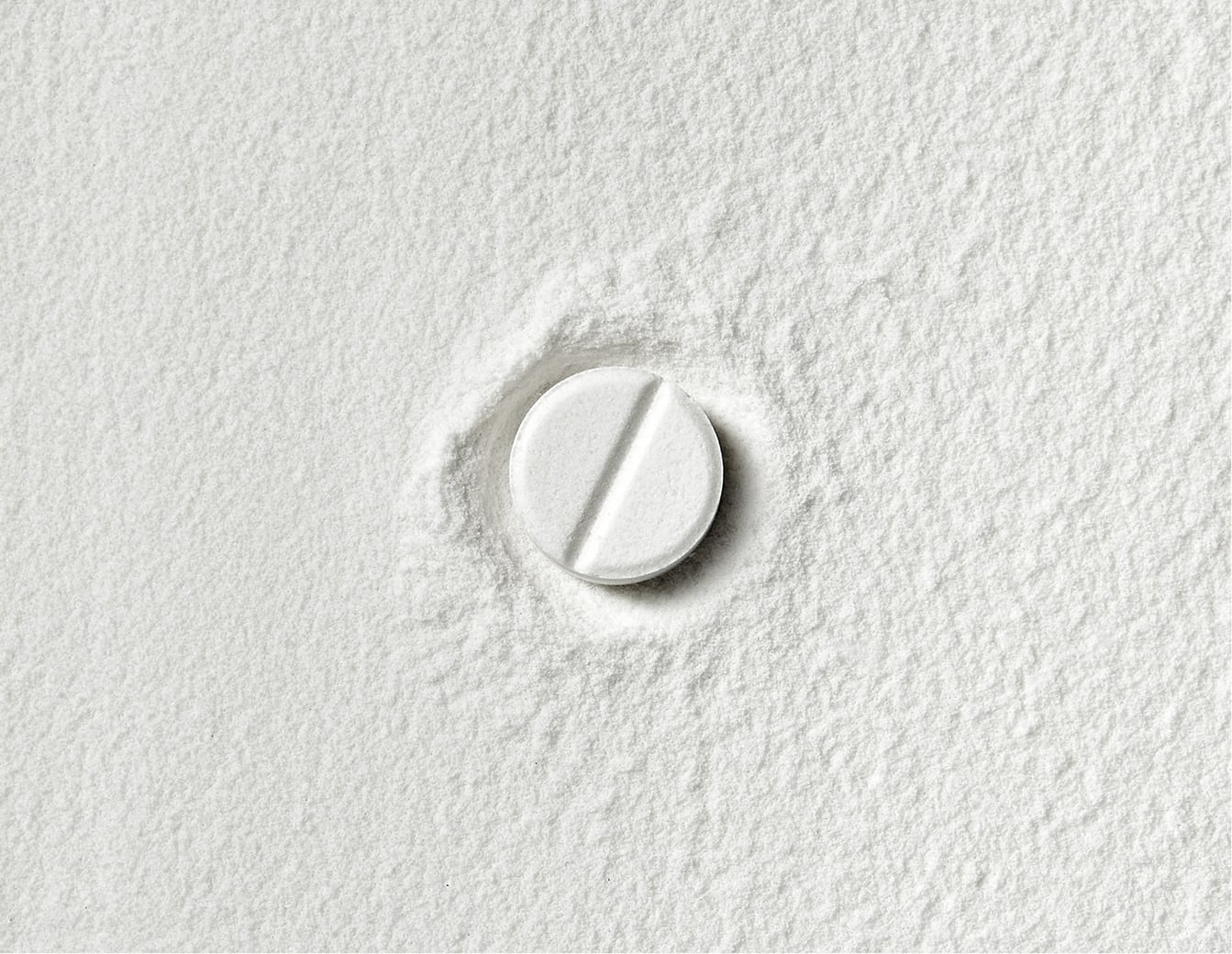

PURA Series™ Super Flow

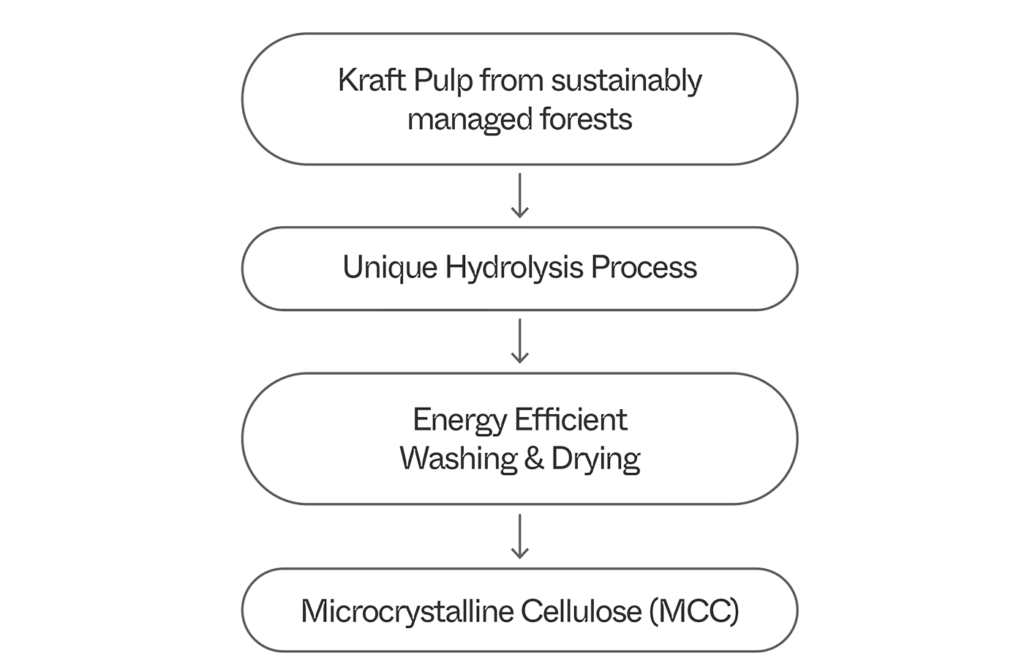

The PURA Series™ Super Flow is our flagship, top-quality product range, featuring unique spherical particle shape, high bulk density, and exceptional flowability. These products ensure consistent performance across diverse applications, including pharmaceuticals, nutraceuticals, personal care, and cosmetics.

The PURA Series™ Super Flow stands out for high purity, exceptionally low nitrite levels, and minimal environmental footprint. These granules offer tailored solutions to meet specific formulation needs, combining sustainability with outstanding manufacturing efficiency and product integrity.